Your specialist for treatment of minerals and environmental technologies.

We offer solutions for the wet mechanical and water management processing.

We are your specialist for treatment of minerals and environmental technologies.

We offer solutions for the wet mechanical and water processing.

AKW Equipment + Process Design is a medium-sized, privately owned company focused on process engineering, equipment manufacturing as well as plant construction and service.

Proudly we can look back to more than 50 years of AKW Equipment + Process Design!

Fifty eventful years, during which we were able to master enormous challenges and develop individual solutions for our customers’ exciting projects.

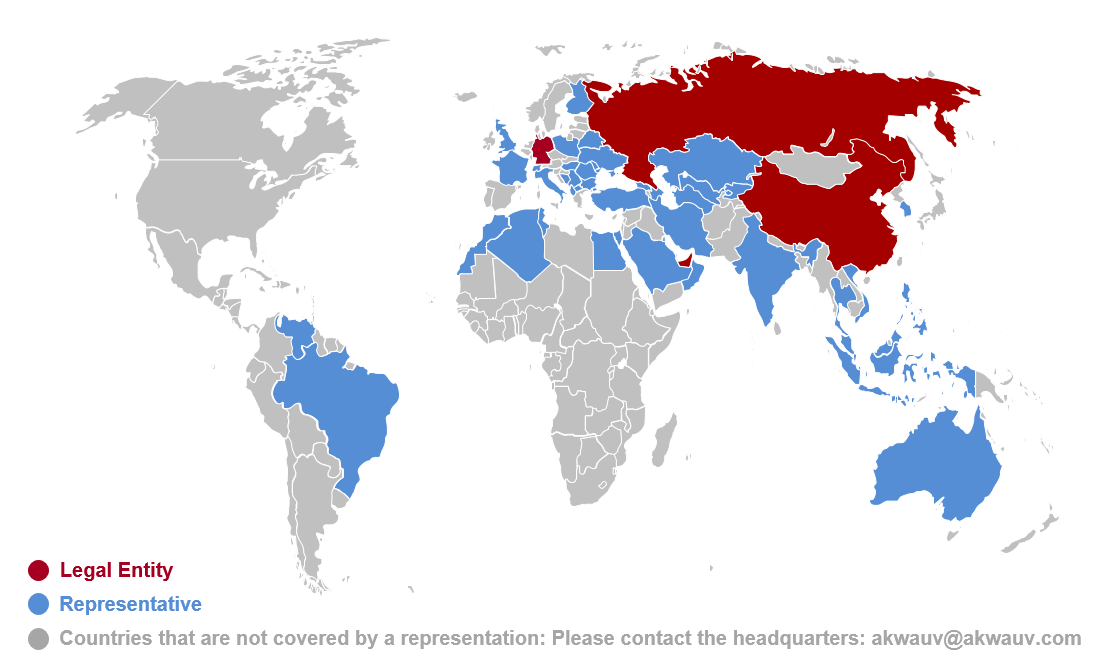

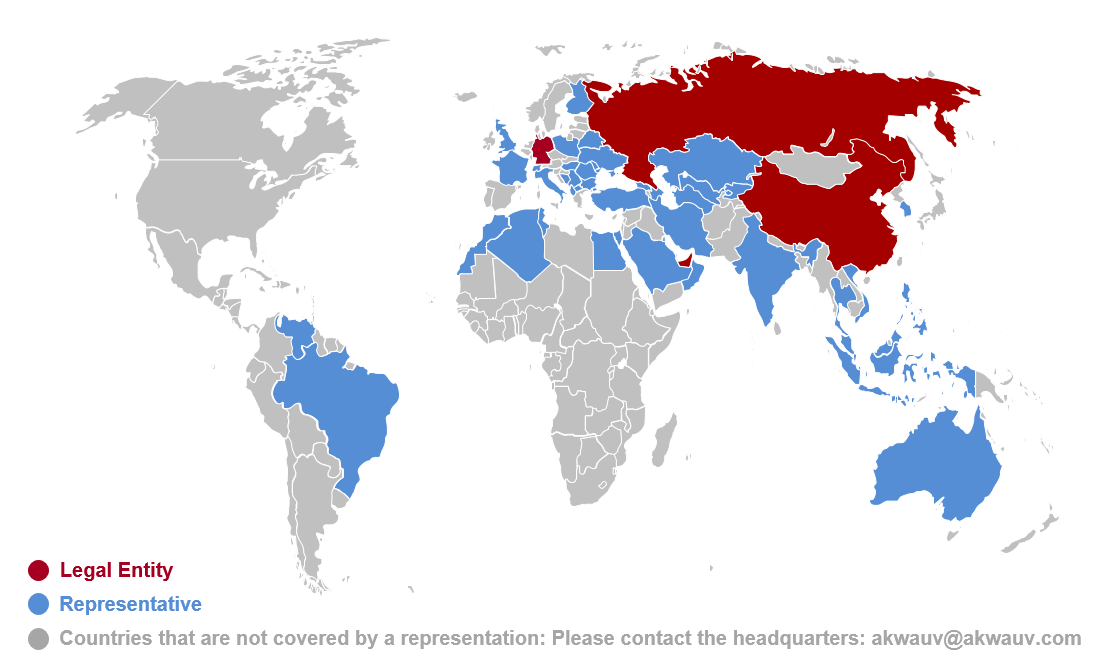

Your Global Partner

Our experts are available worldwide, doesn’t matter if it is a joint venture, associate company or a representative network.

AKW Equipment + Process Design is looking forward to meeting you ! THE BEST OF WET MECHANICAL TREATMENT FOR OPTIMAL AND RESPONSIBLE VALORIZATION OF PRIMARY AND SECONDARY RESOURCES

For any inquiries or questions, please call:

+49(0)9622 7039-0 or fill out the following form